Tyre changers are high-force machines. During mounting and demounting, they apply extreme pressure to tyres and rims. If even one spare part is poorly designed or incompatible, the result is predictable: scratched alloys, bent rims, operator injuries, and angry customers.

OEM compatible tyre changer spare parts exist to eliminate these risks—without forcing workshops to pay inflated OEM prices.

Let’s be clear: tyre changing is not an area where “adjust kar lenge” works.

Why Compatibility Matters in Tyre Changers

OEM compatible tyre changer spares are engineered to match the original machine geometry, force limits, and material behavior.

When compatibility is correct, the machine delivers:

- Correct clamping force – strong grip without rim distortion

- Smooth bead breaking – controlled force instead of sudden shocks

- Controlled tyre movement – predictable motion throughout the cycle

Incompatible or low-grade spares cause:

- Wheel slippage

- Excessive force spikes

- Increased risk of rim cracking and bead damage

That’s not just inefficiency—that’s a safety issue.

Key Tyre Changer Spare Parts That Impact Safety & Performance

These components directly interact with the wheel and tyre and cannot be compromised:

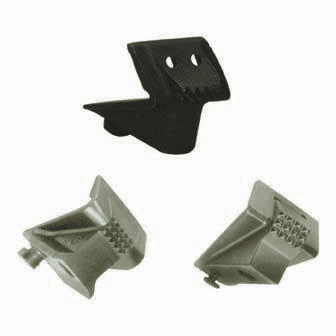

🔧 Mounting & Demounting Heads

These guide the tyre on and off the rim. Poor-quality heads scratch alloys and require extra force to operate.

🔨 Bead Breaker Blades & Pads

Responsible for separating the bead from the rim. Incorrect profiles or worn pads cause uneven force and tyre damage.

🛞 Clamps & Jaws

They hold the wheel securely. Inaccurate jaws either slip or over-clamp—both are dangerous.

🛡 Nylon Rim Protectors

Small, inexpensive parts that prevent expensive alloy wheel damage. Skipping these is pure negligence.

Each of these parts must meet dimensional accuracy, surface finish, and material strength standards to function safely.

Safety & Efficiency Benefits of OEM Compatible Tyre Changer Spares

When workshops use properly manufactured OEM compatible spares, the benefits are immediate:

✅ Prevents Alloy Wheel Damage

Correct profiles and protective materials eliminate scratches and gouges.

✅ Reduces Operator Fatigue

Smooth operation means less manual correction and force application.

✅ Ensures Consistent Performance

Every tyre behaves predictably—no surprises, no rework.

Safety in tyre changing is not optional; it’s a direct reflection of spare part quality.

Cost & Downtime Reduction for Workshops

Original spares are often:

- Overpriced

- Slow to arrive

- Unavailable for older models

OEM compatible tyre changer spares allow workshops to:

- Replace worn parts immediately

- Keep machines running daily

- Avoid revenue loss from idle equipment

Lower cost without performance loss is the only rational business decision here.

Sarveshwari Engineers Focus on Durability

Sarveshwari Engineers manufactures OEM compatible tyre changer spare parts with a clear engineering priority:

- Wear-resistant materials

- Protective surface coatings

- Precision machining for exact fitment

- Long service life under continuous load

These spares are designed for real workshops, not showroom demonstrations.

Straight Truth to End With

If a workshop is still damaging alloys or struggling with stiff tyre changers, the machine is usually not the problem—the spare parts are.

OEM compatible tyre changer spares are essential because they:

- Protect wheels

- Protect operators

- Protect workshop reputation

📩 Call to Action

Contact Sarveshwari Engineers for OEM-compatible tyre changer spare parts that deliver safety, efficiency, and durability—without OEM pricing pressure.